In the procurement industry, large organizations often face significant challenges when managing data across multiple Enterprise Resource Planning (ERP) systems.

A global company with diverse business units encountered a common yet complex issue: inconsistent item naming across its ERP systems.

This lack of standardization hindered the procurement team’s ability to gain a unified view of purchases, leading to inefficiencies, missed opportunities for cost savings, and operational silos.

The company sought a scalable, productized solution to harmonize its item data, enabling better spend analysis and procurement consolidation.

PSA, an agentic system powered by Oraczen’s Zen Platform, delivered AI-powered data harmonization capabilities to standardize and enrich item data across ERP systems, resulting in measurable improvements in procurement efficiency and visibility.

Industry Context

The procurement industry often grapples with data harmonization challenges, particularly for global organizations with decentralized operations. According to a 2024 Gartner report, over 60% of large enterprises struggle with inconsistent data across ERP systems, leading to an average of 15% overspending due to missed consolidation opportunities.

AI and machine learning are increasingly adopted to address these challenges, enabling enterprise-grade automation in item standardization, supplier consolidation, and procurement analytics.

The Problem: Inconsistent Item Data Across ERP Systems

The company operated with multiple ERP systems, each used by different business units with varying naming conventions for the same items.

Example: An item might be labeled as "A" in one system, "A*" in another, and "B" in a third — despite being the same product.

This inconsistency created multiple issues:

Lack of Visibility – The procurement team could not accurately track purchases across the organization, making it difficult to identify opportunities for bulk purchasing or supplier consolidation.

Inefficient Spend Analysis – Without standardized categories, spend analysis was fragmented, leading to missed savings.

Manual Mapping Challenges – The company initially considered creating a manual mapping table… [Initial manual mapping attempts were labor-intensive, error-prone, and unscalable.]

Data Discrepancies – Variations in descriptions made identifying related items nearly impossible, limiting optimization opportunities.

The Solution: AI-Driven Data Harmonization and Clustering

The company operated with multiple ERP systems, each used by different business units with varying naming conventions for the same items.

Phase 1 – Data Enrichment and Clustering

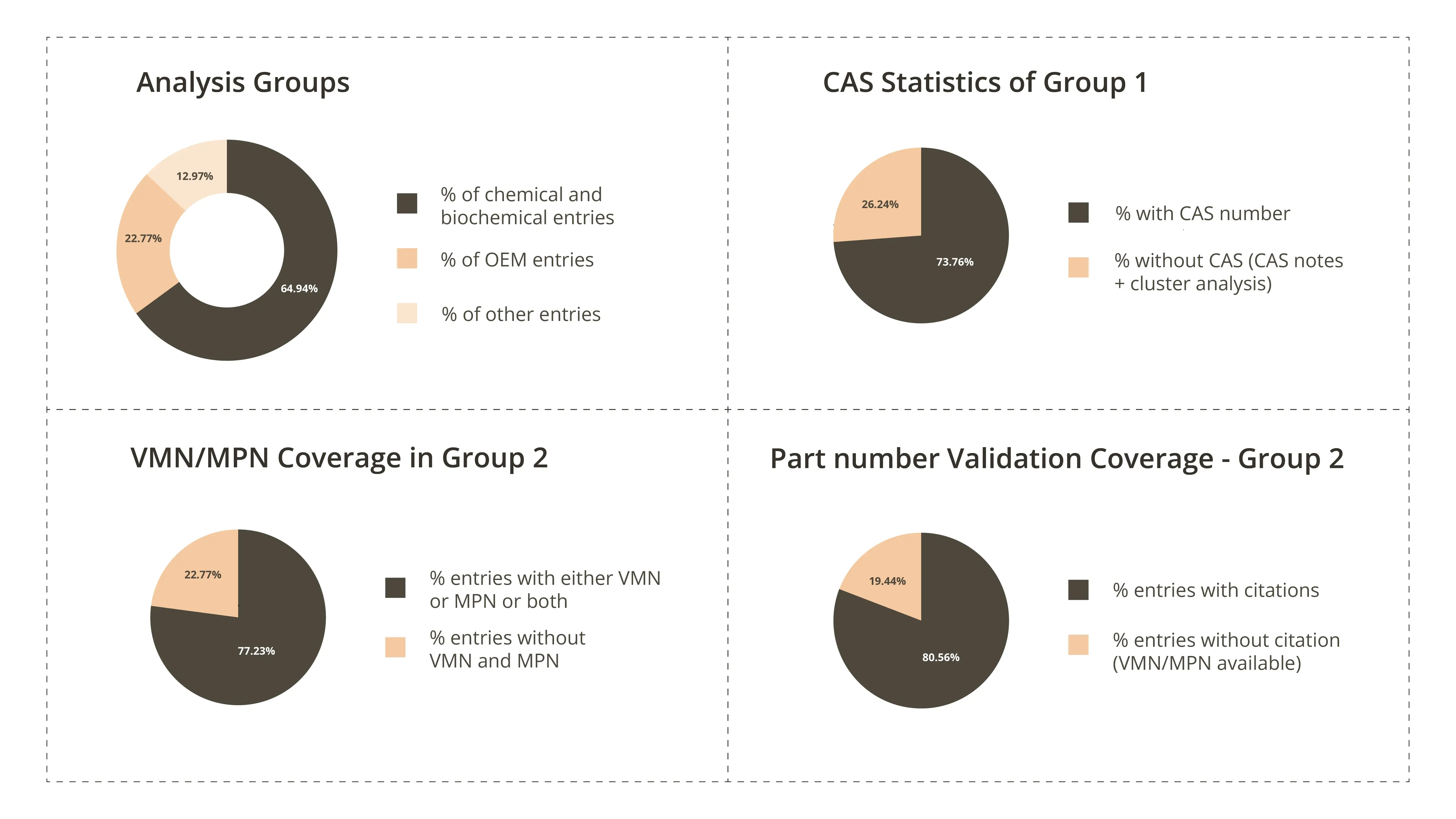

Data was segmented into three groups for specialized enrichment:

1. Chemical & Biochemicals

- CAS Enrichment – Added Chemical Abstracts Service (CAS) numbers for precise identification, based on descriptions, supplier L1, and manufacturer name.

- CAS Not Possible: Notes – Where enrichment was not possible, detailed notes explained data gaps.

2. OEM Vendors with MPN/VMN

- MPN/VMN Enrichment – Manufacturer Part Numbers and Vendor Material Numbers were appended using AI.

- Validation with Source Citation – All enrichments were validated and cited for traceability.

3. All Other Items

- Dimensional Enrichment – Added attributes such as type, functionality, industrial use, molecular name, and technology group.

Clustering and Analysis – AI grouped similar items across naming variations and analyzed clusters for patterns, adjacencies, and cost opportunities

Phase 2 – Feedback Loop and Standardization

- Standardizing Descriptions – Clustered items were assigned unified descriptions in ERP systems.

- Improving Data Quality – Naming conventions updated to prevent future discrepancies.

- Ongoing Maintenance – Procurement team maintained standardized data using PSA’s AI-generated clusters.

Technology and Approach

- Natural Language Processing (NLP) to analyze descriptions across ERP systems.

- Clustering Algorithms to group items by enriched attributes.

- External Data Integration for CAS, MPN, VMN, and industrial classification.

Results and Benefits

- 85% Reduction in Naming Discrepancies – Unified descriptions across identical products.

- 17% Procurement Cost Efficiency – Consolidated purchasing reduced supplier variation.

- 90% Time Savings – Dramatic reduction in manual mapping workload.

- 20% Supplier Base Reduction – Improved leverage and streamlined operations.

- Adjacency Insights – Identification of related items for procurement strategy expansion.

Testimonial

A procurement manager noted:

“Before this capability, our team spent significant time trying to align item data across systems. PSA automated this process and revealed savings opportunities we hadn’t considered. It’s materially changed how we manage procurement.”

Challenges and Lessons Learned

- Data Gaps – Some items lacked sufficient details for enrichment.

- Stakeholder Buy-In – Early results were key to securing adoption.

- Change Management – Updating ERP systems required cross-unit coordination.

Conclusion

By deploying PSA’s AI-driven harmonization capability, powered by Oraczen’s Zen Platform, the company eliminated a critical barrier to enterprise procurement optimization. The solution now serves as a repeatable, scalable model for harmonizing multi-ERP item data across industries..